Not all connector contacts are reel-to-reel plated. There are two batch plating processes and two non-electrolytic practices worthy of a brief discussion.

Batch Plating

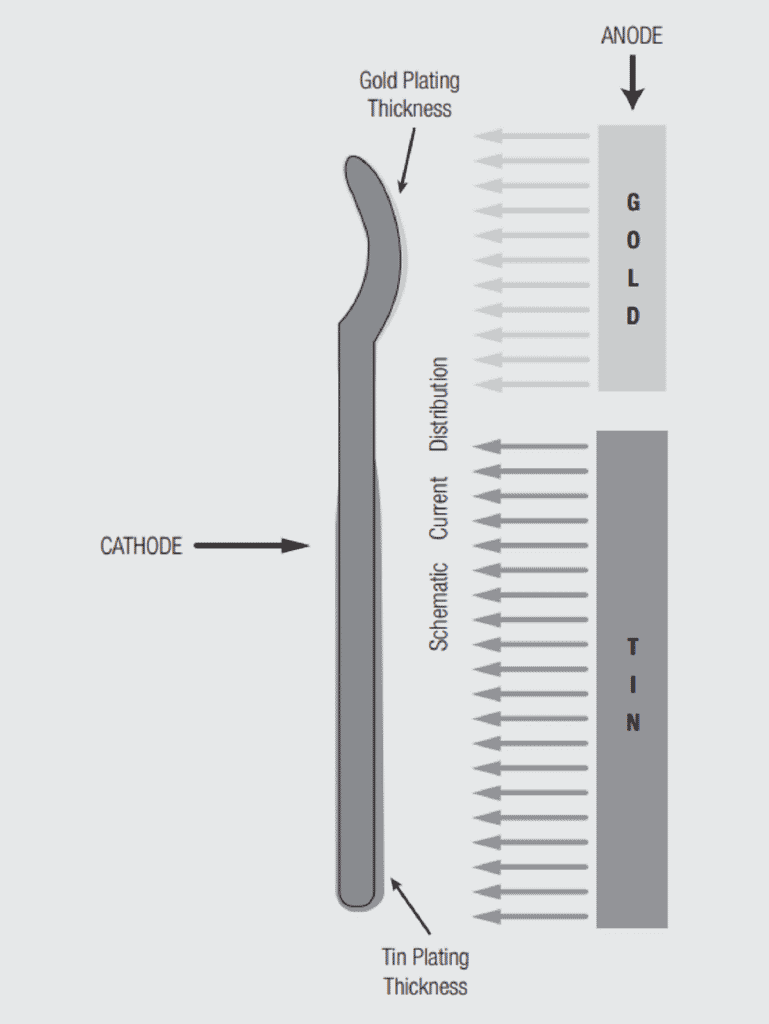

The two batch plating processes differ in how the contacts are presented to the plating bath. In one case, commonly called “barrel plating” the contacts are simply placed in the barrel and incidental contact between individual contacts is relied on to retain continuity of the cathode. The contacts are generally tumbled to promote greater uniformity of plating thickness. In the second case, the contacts are attached in some manner to a frame or rack which is made the cathode during the plating process. Batch plating is used primarily for tin plated contacts intended for industrial and white goods applications.

Electroless Plating

The electrochemical reactions that give rise to electroless plating can be quite complicated. For our purposes it is sufficient to say that electroless plating consists in one metal replacing another due to a difference in electrochemical potentials without any external power, hence, electroless. Electroless plating is sometimes called immersion plating because it occurs on immersion without external power. Nickel, gold, silver and copper can be electroless plated. Benefits of electroless plating are that it plates uniformly over a surface, thus can plate into recesses and blind holes not amenable to electroplating. Limitations of electroless plating are speed and limited thickness capability, fractions of a micron. The process essentially stops when the entire surface being replaced has been covered over.

Hot Air Reflowed Tin (HART)/Hot Air Solder Leveling(HASL)

These processes are similar in that a tin or solder coating is applied and a hot air “knife” is used to level the coating. HASL is typically used in printed circuit board applications.