To discuss connector applications, recall from 1.1 the following functional definition of a connector:

“A connector is an electromechanical system which provides a separable connection between two sub-systems of an electronic device without an unacceptable effect on the performance of the device”

In that same section it was noted that “unacceptable effects” were primarily related to the magnitude and stability of the connector resistance. The magnitude and stability requirements are dependent on whether the application requirement is to carry a signal or distribute power.

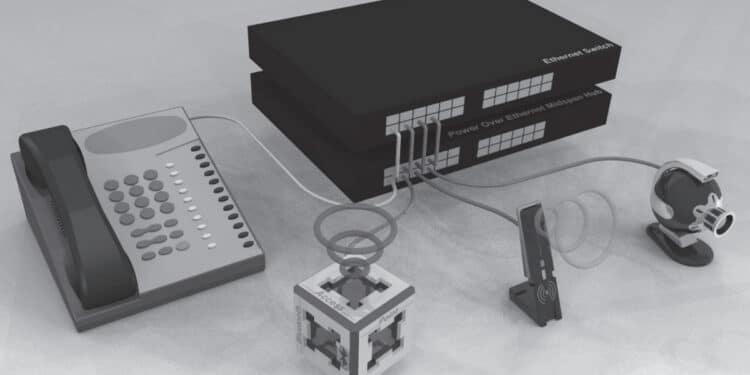

All connector applications include a mix of signal and power functions. The signal functions activate/control various subassemblies within the system and the power functions ensure that adequate current and voltage is available to the subassemblies.

In industrial/commercial applications many of the signal functions, driving timers and switches for example, are not very demanding in terms of current, voltage and resistance requirements. Increasingly sophisticated computer control functions, however, are bringing more demanding requirements into such applications and computer/telecom applications are critically dependent on signal integrity. Signal integrity, maintaining the shape and amplitude of a signal, depends on a complex interaction of connector geometric and material characteristics. Connectors have evolved to meet these demands.

Similar comments apply to power distribution. Power demands have risen dramatically as the functionality of electrical and electronic systems has increased in recent years. In power connectors the dominant concern is the Joule, I2R, heating that accompanies increased power levels.

Connectors have evolved to address these requirements in two ways, dedicated high current contacts and current distribution through connectors using multiple lower current contacts in parallel.