This chapter will provide an overview of design and material requirements for contact finishes, contact springs and connector housings as well as the major degradation mechanisms for these connector components. Material selection criteria for each will also be reviewed.

Contact Finishes

Contact Finish Requirements

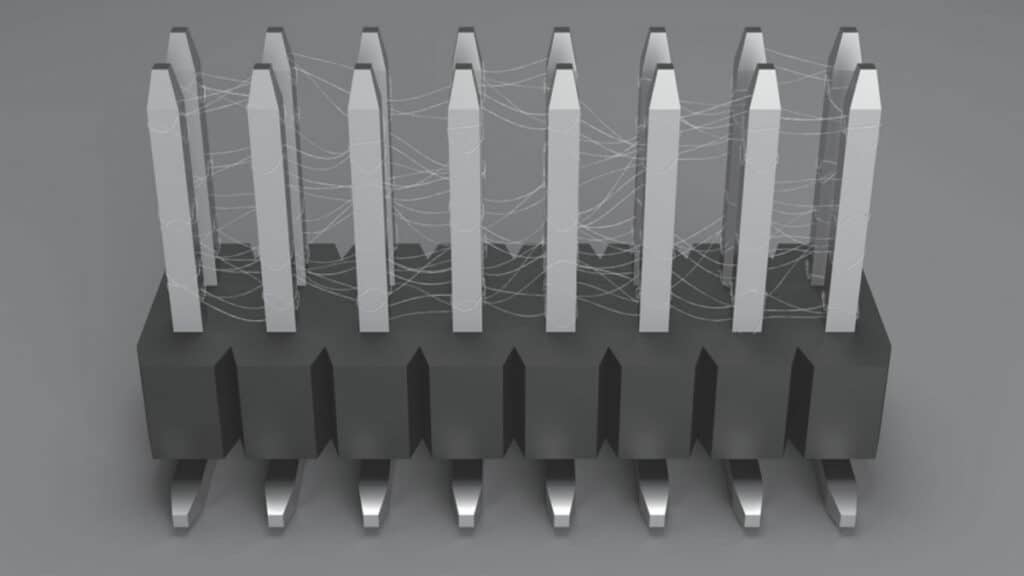

As noted in Chapter I/1.2.3 Contact Finishes, a contact finish is applied to connector contact springs to provide two basic functions:

• to protect the copper alloy spring members from corrosion

• to optimize the mechanical and electrical performance of the contact interface.

As noted in Chapter I/1.2.2 Contact Springs, connector contact springs are generally made from copper alloys due to their combination of high electrical conductivity and formability at reasonable strength levels. Unfortunately copper alloys are susceptible to corrosion in environments containing oxygen, sulfur and chlorine, in other words typical connector operating environments. Thus, the first function of a contact finish is to protect the copper alloy spring from corrosion.

Corrosion protection can be provided by simply coating the contact spring with a material which is not susceptible to corrosion or, in connectors, a material which forms films which are self limiting in thickness and readily displaced mechanically during the mating of a connector. Gold is the prime example of the first case and tin of the second. Each of these cases will be discussed later in this chapter.

“Optimization” of contact interface performance is provided by influencing the corrosion and wear characteristics of the contact interface. Corrosion protection is necessary in order to ensure that metal-to-metal a-spot contact interfaces can be created and maintained as discussed in Chapter I/1.3.1 Overview. Recall that chapter. We also note that creating and maintaining a metal-to-metal interface is the prime goal of connector design. A gold-to-gold contact interface is intrinsically metal-to-metal because gold does not corrode. A tin-to-tin contact interface becomes metal-to-metal when the surface tin oxide is displaced on mating of the connector. There are some qualifications to this simple description that will be discussed later in this chapter.

“Optimization” of contact interface wear characteristics is particularly important with gold contact finishes. The concern is that the wear that occurs on each mating cycle can result in wear through of the contact plating exposing the underlying copper alloy which is then susceptible to corrosion. The wear performance of gold finishes can be improved by increasing the hardness of the gold by alloying and by increasing the effective hardness of the gold by using a nickel underplate.

Consider noble metal finishes first.