A contact finish, C in Figure 1.3, consists of a surface coating, generally produced by electroplating, over the contact spring to provide two performance benefits:

Corrosion protection for the contact springs and optimization of the electrical and mechanical characteristics of the contact interfaces. As mentioned, copper alloys are typically used as connector contact springs and are susceptible to corrosion in typical connector operating environments. The contact finish provides corrosion protection by covering the exposed copper to protect it from the operating environment. “Optimization” of contact interface performance is provided by influencing the corrosion and wear characteristics of the contact interface. These functions will be discussed in Chapter II.

There are two general types of contact finishes, noble and non-noble. Gold is the predominant noble metal finish material. The term “noble” refers to the fact that gold is not susceptible to corrosion. Tin is the most common non-noble finish material. Tin is susceptible to corrosion by the formation of a thin self limiting thickness of tin oxide. This oxide protects the contact interface from further corrosion, but is readily displaced on mating of the connector to provide the desired metal-to-metal contact interface.

A brief overview of each finish will be provided here with details to follow in Chapter II/2.1 Contact Finishes.

Noble Contact Finishes

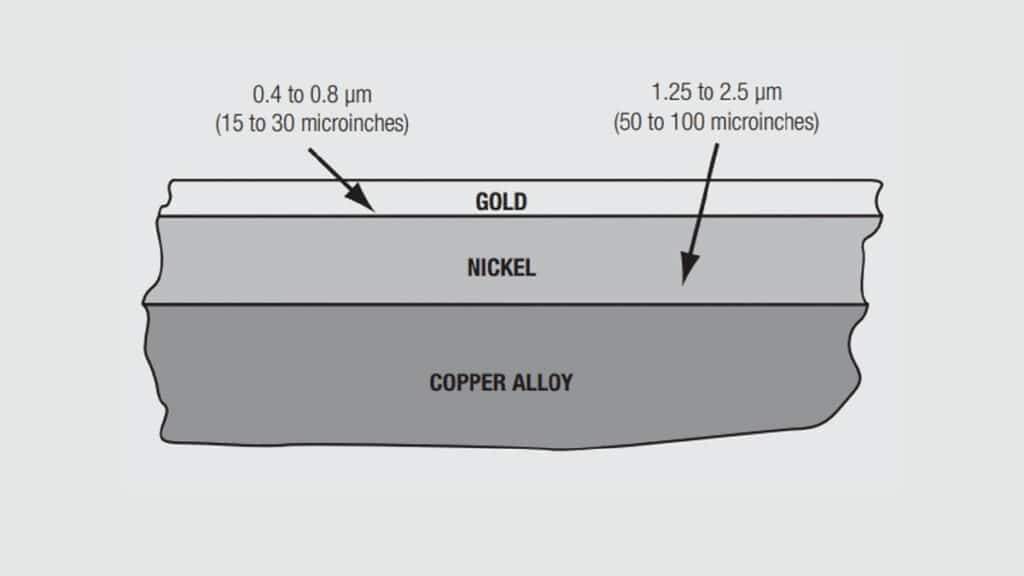

A noble metal finish is a system consisting of three components. A surface coating of noble metal, gold or palladium alloy, an underplate, generally nickel, and the base metal of the contact spring as shown in Figure 1.14. For Telecom or harsh environment gold and nickel are typically electroplated to thicknesses of the order of 0.4 to 0.8 µm (15 to 30 microinches) for gold and 1.25 to 2.50 µm (50 to 100 microinches) for nickel. Noble metal finishes are used in high performance and high reliability applications.

The gold top coat provides the corrosion protection. It also allows for performance optimization in that the hardness of the gold can be controlled to influence the friction and wear behavior of the mating interface. The nickel underplate provides several performance advantages noted here for reference with details to follow in Chapter II/ Design/Selection/Assembly.

The nickel underplate:

• reduces the susceptibility to pore corrosion

• reduces corrosion migration

• provides a diffusion barrier to base metal migration

• improves the mating durability of the contact interface

The contact spring is included in the noble metal finish system for both electrical and mechanical reasons. The electrical reason is that the distribution of the current flow to the contact interface is dependent on the conductivity of the contact spring. The mechanical reason is that the stresses applied to the contact interface during mating can extend down into the spring material due to the small thicknesses of the gold and nickel platings.

Non-noble Contact Finishes

The dominant non-noble finish is tin, with silver and nickel being used in selected applications. Tin is used in industrial and commercial applications including white goods, while nickel and silver are primarily used in battery contact and power contacts respectively.

These finishes are also typically electroplated, but tin can also be applied by dipping or reflow processes. Tin finish thicknesses are in the range of 2.5 to 5.0 µm (100 to 200 microinches). Nickel and silver thicknesses are generally in the range of 1.25 to 2.5 µm (50 to 100 microinches).