Connector contact lubricants are used to provide two different performance benefits; reduction in friction and corrosion protection. Reducing friction will reduce connector mating forces and increase connector mating cycle life. Lubrication can also reduce the susceptibility to corrosion, both fretting and environmental, and enable the use of the connector in harsher environments.

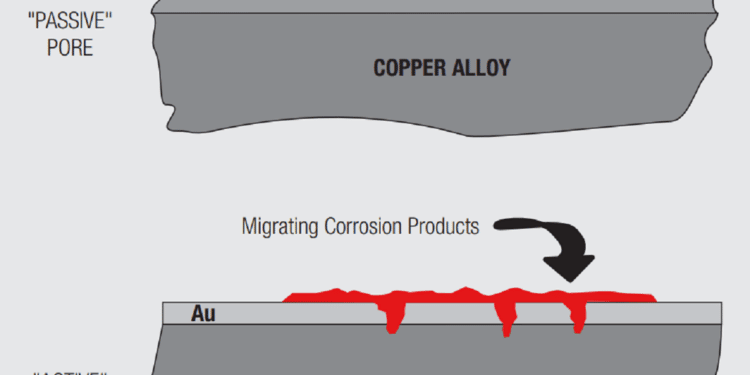

For noble metal contact finishes, friction reduction is an obvious benefit with respect to mating durability allowing the connector to be specified for a higher number of mating cycles, or to meet a given mating cycle requirement with a reduced gold thickness. Reduction in mating forces is also important and can allow higher pin count connectors to be realized or allow the use of higher contact forces, enhancing mechanical stability, at a given mating force. Corrosion protection may also be important in reducing the potential for corrosion of exposed copper alloy in more demanding environments.

For tin contact finishes, the benefits of lubrication, in reducing the potential for fretting corrosion, are dominant. The benefits of reductions in friction are not as significant for tin finishes because the intrinsic durability of tin is low, due to the low hardness of tin. The high contact force typical of tin contacts, to provide mechanical stability, results in a high mating force which can be moderated by lubrication, but the pin count capability of tin connectors is still limited. Silver plated contacts benefit primarily from corrosion protection to reduce the potential for surface tarnish.

The components of a lubricant that reduces friction and a lubricant that provides environmental protection are different and, therefore, different formulations are necessary for noble and non-noble finish systems. Contact lubricant formulations are proprietary, but some general comments on lubricant components are possible.

The basic component is a solvent, or solvents, that can take all of the necessary active components into solution for ease and consistency of application. Application methods include sprays, dips and brushes/pads.

The friction reducing component of the formulation is an oil and/or wax. An oil may wet the surface and provide complete coverage. Waxes do not generally wet the surface yielding incomplete coverage. The waxes, however, may smear over the surface as the connector is mated enhancing the effective coverage.

Control of the lubricant viscosity is also important. The lubricant must balance an ability to cover the contact surface initially, be displaced out of the contact interface when the connector is fully mated and flow around the contact interface to provide an environmental “seal”.

A contact lubricant may also contain one or more corrosion inhibitors, or surface wetting agents to inhibit access of the corrosive species to the contact surface.

Finally, ultra-violet tracers are often added to provide “after the fact” evidence that the contact lubricant has been applied. While the potential performance benefits of contact lubricants are obvious, they also have limitations.

Application of the lubricant requires an additional process step. In some cases the lubricant can be applied at the end of the contact plating line by a dip or spray. In other cases secondary operations to apply the lubricant may be necessary. In either case there will be incremental costs of application.

Control of the quantity of lubricant applied may be necessary. While an appropriate amount of lubricant must be applied, excess lubricant may be a liability. This is particularly significant if the lubricant has a tendency to retain dust or contaminants in storage or in the field.

The lubricant may have a limited temperature dependent effective lifetime due to evaporation, flow from the contact interface or component degradation.

Despite these limitations, contact lubricants, when properly chosen and formulated, provide an opportunity to enhance the performance of connectors in more demanding environments, or to maintain the performance of connectors with reduced plating thicknesses.