In a new white paper from Samtec, “Improved Solder Joint Integrity for High-Density Interconnect Applications,” the authors, Robbie Huffman and David Decker, detail the design characteristics and verification testing used to validate the robustness of the solder joints as well as the signal integrity in these next-generation board-to-board (B2B) surface mount area arrays (SMAAs).

Small, complex, and portable applications (in industries such as military/aerospace and medical) require miniaturized, reliable interconnects. As traditional surface-mount and through-hole interconnects reach their limits in terms of density and the number of signals that can effectively be used, many product designers are implementing high I/O array styles of interconnects.

While pin-in-ball SMAAs have been widely used in the industry for decades, they have lacked IPC classification. The demand for B2B SMAAs compatible with IPC-A-610 and IPC J-STD-001 Class 3 acceptance criteria is increasing as these types of interconnects are necessary to advance the state of the art for space-constrained applications in areas such as medical and military/aerospace design. The work in this paper shows that next-generation grid array interconnects meet the solder joint reliability and signal integrity performance required to support these high-reliability high-speed applications.

The white paper steps through detailed analysis of the new SMAA connectors, including improved automated x-ray inspection (AXI) as well as reliability testing per IPC-9701 and EIA-364-1000 test methods. The analysis includes both pin-in-ball and non-solder ball versions.

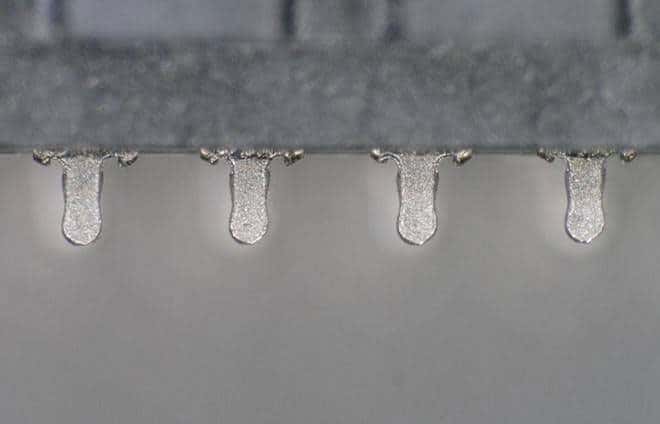

The tail of the next-generation pin-in-ball grid array component incorporates a fully plated, rounded, and coined bottom with contoured sides for increased robustness and an attached collapsible solder ball (Figure 1). These components are typically soldered to round land patterns. Samtec also offers non-solder ball versions, which use the same tail style but are soldered with increased solder paste volume in lieu of an attached solder ball (Figure 2).

The contoured tail style allows deeper tail penetration and an increased solderable surface area with signal integrity performance that supports data rates up to 112 Gbps PAM4 (56 Gbps NRZ) with robust and reliable solder joints that meet industry standards.

You can freely access the white paper in the Samtec Technical library to see the specific test methods and simulations used as well as the inspection criteria. The key takeaway is: Next-generation grid array interconnects can be used for advanced and future applications. Samtec currently offers AcceleRate® and AcceleRate®HP products with this lead style and has several other products in development. The test data collected in this research as well as deployment in major OEM applications validate the robustness of the solder joints and support that this design meets or exceeds all current expectations and requirements for SMAA technologies.