The new four- and five-position 9176-700 Series connectors from KYOCERA AVX provide robust and reliable gas-tight wire-to-board connections ideal for an even broader range of demanding automotive, transportation, industrial, lighting, and medical applications.

FOUNTAIN INN, S.C. (March 30, 2023) – KYOCERA AVX, a leading global manufacturer of advanced electronic components engineered to accelerate technological innovation and build a better future, added new four- and five-position models to its 9176-700 Series capped insulation displacement contact (IDC) connectors for 18–24AWG wire, which are engineered to satisfy the demanding requirements of automotive, transportation, industrial, lighting, and medical applications.

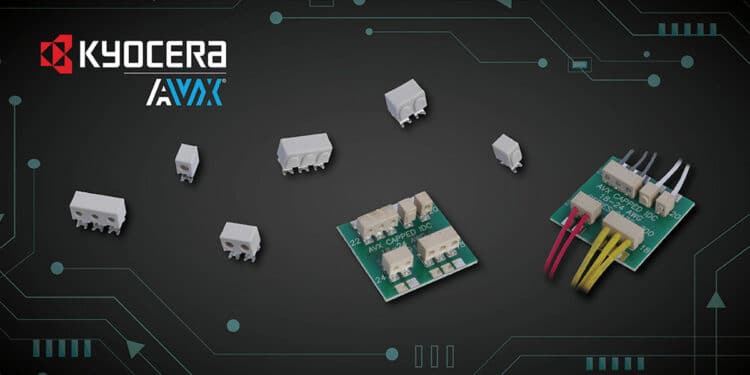

9176-700 Series capped IDC connectors have a user-friendly, low-profile surface-mount form factor with an integrated termination/retention cap that allows users to simply insert a wire into the contact — no stripping required — and press it down to provide a robust and reliable gas-tight connection to the PCB. This quick and efficient process doesn’t require any tools or solder, which reduces both complexity and cost compared to solder and crimp processes, and the resulting connections have been tested to various levels of shock, vibration, and temperature cycling.

The 9176-700 Series is available in through-wire and wire-stop variants for maximum flexibility. Through-wire models allow wires to be terminated at any point, while wire-stop models terminate the end of the wire and have a stop face feature to protect the wire end. These connectors are available with 1–5 positions capable of terminating 18AWG stranded wire or 20–24AWG solid or stranded wire and are rated for up to 10A per position depending on wire size. Single-contact 9176-700 Series connectors are rated for 600VACRMS or the DC equivalent. Two- through five- connectors are rated for 300VACRMS or the DC equivalent. The series is also rated for operating temperatures extending from -40°C to +125°C and storage temperatures extending from -40°C to +70°C.

Ideal applications for the 9176-700 Series include connecting discrete wires to a PCB, bringing power and signal to a PCB, and daisy chaining PCBs together to create a continuous string in electronic devices including LED lighting, oil & gas detonators, disposable surgical tools, medical diagnostics, patient monitors, and automotive and transportation lighting, fuel control valves and modules, and door handles.

“Our 9176 Series surface-mount IDC connectors have been providing design engineers working in challenging industries with attractive size and performance options for reliable discrete wire-to-board connections since their market introduction in 2007,” said Perrin Hardee, North American Product Manager, KYOCERA AVX. “They have been tested to various levels of shock, vibration, and temperature cycling to prove their reliability and robustness and field-proven in hundreds of applications ranging from smart meters to simple sensor terminations. Expanding our 9176-700 Series with new four- and five-position models allows us to meet the needs of evolving markets and applications and — by virtue of its unique integrated termination/retention cap, which serves as a wire location and insertion aid — to provide design engineers with even more opportunities to simplify and reduce the cost of bringing power and signal to a PCB.”

9176-700 Series connectors have glass-filled high-temperature UL94 V-0 Nylon insulators and high-strength phosphor bronze contacts with pure tin over nickel plating. They also share a contact and footprint pattern with the rest of the 9176 Series for full backwards compatibility.

White insulators are standard, but the entire series is also available with black insulators. In addition, single-position 9176-700 contacts are available with blue, yellow, red, green, orange, and brown insulators by special order.

The 9176-700 Series is compliant with RoHS and UL 1977 standards and shipped in tape and reel packaging with 600 parts per 300mm reel. Lead-time for the series is currently eight weeks.