This article based on Samtec blog provides overview of I/O high rel connector options for rugged harsh environments.

Temperature extremes, humidity, dust and other particles, electrostatic discharge, high altitudes, atmospheric gases, and continuous intense shock and vibration. When an engineer hears these conditions being discussed, opportunities to ruggedize a system quickly come to mind. To select the right electronic interconnect for these rugged environments, especially an I/O (input/output) assembly operating outside an enclosure, then it’s best if the interconnect is specifically designed to combat these types of environments for ensuring reliability through the lifetime of the system. This is where URSA® I/O comes in.

URSA® I/O

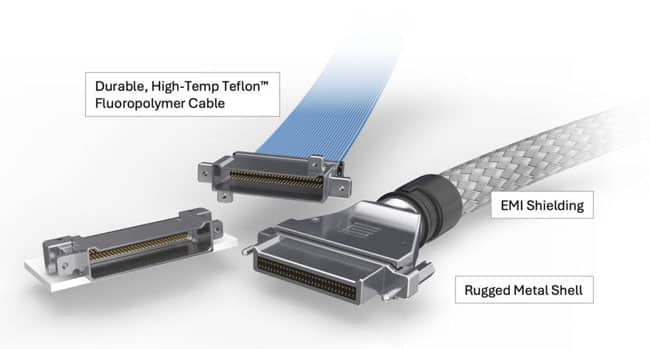

URSA® I/O is Samtec’s go-to I/O cable assembly for rugged environments due in part to the reliable metal shell, EMI shielding, and hyperboloid contact design. It’s a commercial-off-the-shelf (COTS) solution ideal for military, aerospace and space applications. As a COTS solution, it’s readily available ensuring faster time to market and is much more cost effective compared to custom designs.

We proactively test URSA® I/O parts to our Severe Environment Testing (SET) procedures. Reports are readily available; so, a designer can have confidence the product will perform as expected in demanding applications. It also passes our Extended Life Product™ (E.L.P.™) testing with 5,000 mating cycles and 10-year Mixed Flowing Gas (MFG). View our product-specific reports on each Series page under the “Test Reports” tab. Or, following are direct links for B1SDT & P1M-RA Series products: SET Report, ELP Report, MFG Report.

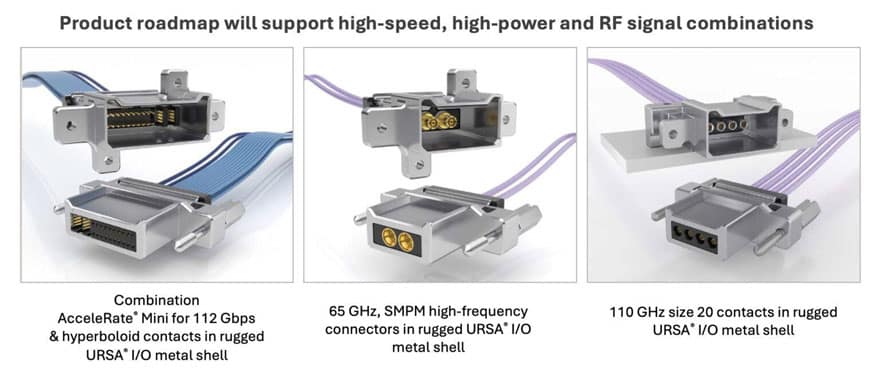

Fully released Series within the URSA® I/O product family are B1SDT, P1PDT and P1M. This initial product release supports low-speed signals and low power applications (3.8 Amps per pin, 2 pins powered) in cable-to-cable or cable-to-board applications. The URSA® I/O product roadmap will support high-speed, high-power and RF signal combinations. Look for these to release over the coming months.

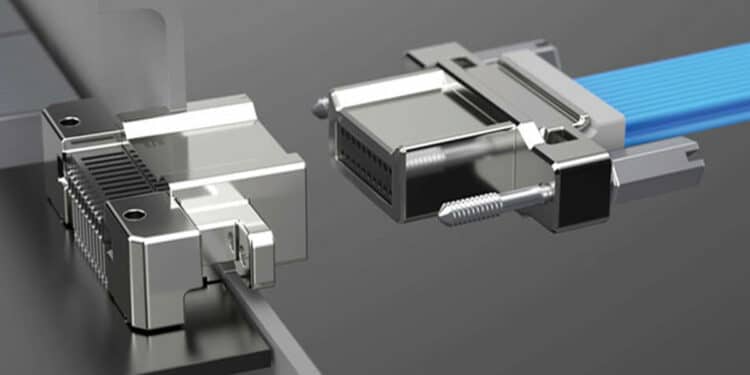

Hyperboloid Contact Design

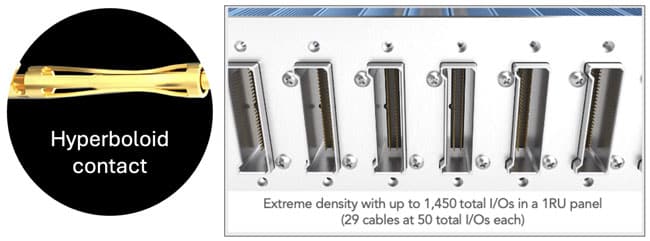

Hyperboloid contacts are trusted in the industry as being highly reliable in harsh environments. Samtec’s hyperboloid contact system is extremely small allowing for higher density connectors. It features four points of contact for extreme reliability and extremely high mating cycles (5,000 mating cycles for URSA® I/O ultra rugged cable system).

Metal Shell, Teflon™ Fluoropolymer Cable & EMI Shielding

The metal shell is well suited for ultra rugged environments. Samtec’s is a cast version, instead of machined, allowing for an extremely cost-effective solution without jeopardizing reliability. The Teflon™ fluoropolymer cable performs well in higher elevated temperatures while the braided metal jacket provides end-to-end EMI shielding (specify –E option in part number).