What is an RF Signal?

First, we should define what RF stands for. An RF (Radio Frequency) signal refers to an alternating current (AC) signal characterized by its frequency falling within the radio frequency range. This typically includes frequencies from 3 kHz (kilohertz) to 300 GHz (gigahertz).

RF signals are widely used in various communication systems, such as radio broadcasting, television, wireless communication, and radar.

If you look across the broader electromagnetic spectrum the selection of the 3 kHz to 300 GHz frequency range for RF signals is a result of a balance between propagation characteristics, data transmission requirements, regulatory allocations, and the compatibility of electronic components and devices.

This range effectively covers a wide array of applications, making it a standard for RF communication and technology.

What is an RF Connector?

An RF connector is simply a device used to connect or terminate coaxial cables, providing a pathway for RF signals between electronic devices. These connectors play a crucial role in ensuring a reliable and efficient transfer of RF signals. RF connectors come in various types, each designed for specific applications and frequencies.

They often have a coaxial structure, consisting of a central conductor, insulating material, and an outer conductor that serves as a shield. The choice of RF connector depends on factors such as frequency, power, and environmental conditions. RF connectors are widely used in telecommunications, broadcast equipment, aerospace, medical devices, and other industries where high-frequency signal transmission is essential.

How are RF Connectors made?

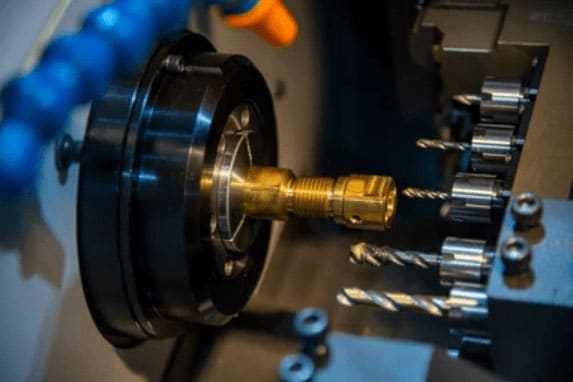

Most RF connectors are manufactured using precision machining processes. The production typically involves the use of high-quality materials like brass, stainless steel, or aluminum. Automated machining tools, including CNC (Computer Numerical Control) machines, cut and shape the connector components to exact specifications. These CNC screw machines are where the cylindrical stock spins as a host of cutting tools work around the central axis.

The connectors consist of a central conductor, insulating material, and an outer conductor, often in the form of a threaded outer shell. Advanced techniques such as electroplating may be employed to enhance conductivity and protect against corrosion. Tight tolerances are maintained to ensure optimal performance and impedance matching. The result is a reliable and durable RF connector ready to facilitate the seamless transmission of high-frequency signals in various electronic applications.