n some cases the selection of an appropriate polymer for a connector housing is determined by a particular advantage or limitation of a polymer. For example, Liquid Crystal Polymers (LCP) have high temperature capabilities that make them suitable for SMT applications. Similarly, the dimensional growth of nylon 66 housings due to moisture absorption limits the dimensions of nylon connector housings. More generally, there are three considerations in the evaluation of whether a particular polymer is a suitable choice for a given connector: the connector function (signal or power), housing manufacturing (connector dimensions and tolerances) and application requirements (SMT).

Signal/Power: There are two categories of signal applications, low current, less than an amp to a few amps, and high speed or high data rate applications, where the impedance of a connector becomes a concern. For the first category, polymer issues are primarily in molding miniaturized connector housings. These concerns will be addressed in Chapter II/2.4.3 Housing Design. For high speed applications the dielectric constant and dissipation factors of the polymer and their stability with respect to temperature and environmental degradation merit consideration. It is the differences in stability that distinguishes among polymers rather than their intrinsic properties, which are generally similar. It should be noted that the impedance of a connector is strongly dependent on connector dimensions as well.

In power connectors surface resistivities can be important due to the potential for voltage breakdown and surface leakage currents. Temperature stability may also be a consideration due to coupling of the Joule heating of the contacts into the housing and the associated increase in housing temperature. As noted in Chapter I/1.4.3 Polymer Materials and Processing the mechanical properties of polymers are temperature sensitive.

Manufacturing: Both property variations with molding and dimensional tolerances are of interest. As just noted, polymer variances in dielectric constant and dissipation factor may affect high frequency performance and the molding process is a significant factor in controlling such variances. Mold design also influences the knit line configuration in the molded housing and weakness in knit lines can be a source of weakness and “brittleness” in the housing. Knit line strength varies with the polymer with LCP being a particular concern because the rod like structure of LCP polymers does not cross the interface between the flow fronts as they meet in the mold.

Dimensional tolerances come into play at both ends of connector housing size. Large connector dimensions, particularly long and narrow housings are susceptible to warp or bow due to polymer anisotropies created by mold fill. Crystalline and glass reinforced polymers tend to orient along direction of polymer flow during molding. Thicker sections, connector outside walls, tend to be more crystalline than the thinner section walls separating connector cavities and shrink more than the thin sections creating the potential for warping and bowing.

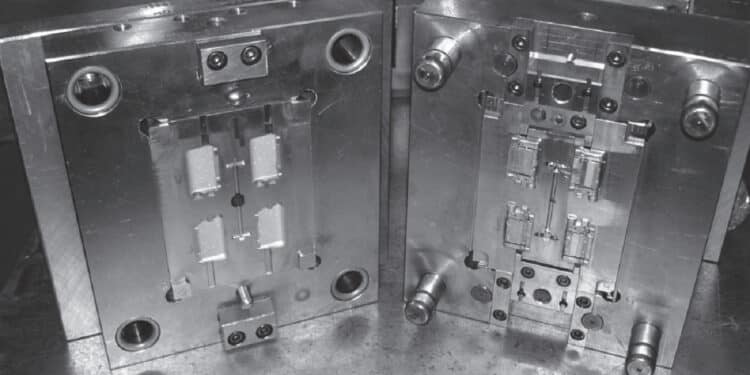

Miniaturized connectors, with small centerlines and thin walls, require good polymer flow during the molding process. High flow polymers, however, are more susceptible to flash, extrusion of polymer through seams in the mold, which is undesirable.

It must be noted that control of the injection molding process is critical to minimizing these polymer and design issues. Melt and mold temperatures, injection and holding pressures, hold-time and cooling profiles, among others, affect crystallization rate and percentage, shrinkage, bow and warp of connector housings.

Application Considerations: Application considerations include component assembly application thermal and chemical environments and application current and voltage requirements. The thermal profiles required for SMT soldering profiles are arguably the most significant assembly issue. The requirements have become even more demanding with the drive towards lead free solders which require higher soldering temperatures. LCP dominate the SMT market. The potential for degradation of polymer surface electrical properties is the major concern with respect to the chemical environment of the application. Moisture must be considered among the chemicals of concern for some polymers, e.g. nylons.

The Continuous Use Temperature (CUT) of an application is also significant because, as noted, the mechanical properties of a polymer are sensitive to temperature as are the rates of chemical reaction. When the contact force system of a connector is supported by the polymer, either directly by a pre-load system, or indirectly, by a retention lance to maintain contact position, the temperature dependence of polymer creep can become a significant concern. With respect to application voltage and current requirements, the concerns are different in the two cases. Voltage issues are primarily safety related and impact on connector design as will be discussed in the next section.

Current issues are performance related, in particular the effect of Joule heating on the connector temperature and the effect of temperature rise on polymer properties as noted previously. The effects of Joule heating will be discussed in Chapter II/2.6 Level of Interconnection.