This technical blog article written by Ajay Saini, KYOCERA-AVX Components Corporation, explains connector requirements and solutions for battery contacts for mobile electronics.

Introduction

When requiring a recharge is an unacceptable constraint for mobile electronics, replaceable battery packs are the only practical option. From cordless power tools to mobile phones to portable defibrillators, the ability to quickly, and reliably, swap an empty battery for a freshly charged one introduces a high level of convenience and trustworthiness to any product.

However, removable batteries add significant overhead to the overall mechanical and electrical design efforts. Mechanically, the battery must be accessible and easy to replace while being sealed appropriately to the environment and secure during operation. Electrically, the battery must make a low resistance connection time and again without adding high cost or size overhead.

KYOCERA AVX offers the broadest standard battery connector line available on the market today. These robust connectors, available in horizontal and vertical options, are suited for battery

pack integration and general board-to-board connection.

Electrical Performance

Two important features that must be considered when evaluating a battery contact are the current to contact rating and mating durability. To achieve ultra-reliable, high integrity connections in harsh environments, KYOCERA AVX generally uses gold-plated beryllium copper contacts. As a result, most products have a contact rating of 3A (finer pitches have a 2A rating) and are rated for 5000 mating cycles.

In addition to the contact surface itself, the mechanical action of establishing the interface is worth considering. Traditional right-angle connectors seen in many products have contact geometries that rely on the battery pack being inserted at an angle and then rotated down into position. This can result in users commonly damaging the contact by not applying the appropriate angle or force to the battery during insertion.

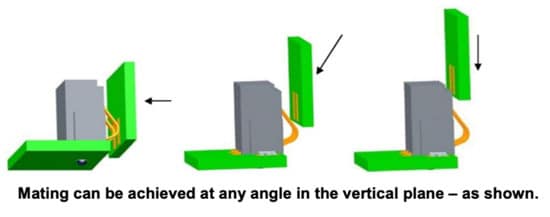

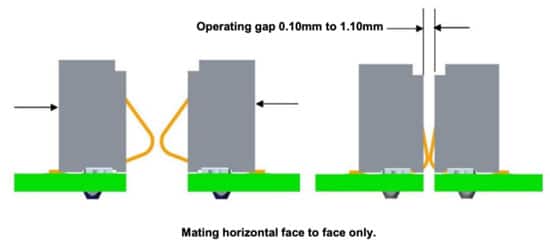

KYOCERA AVX has innovated several contact geometries to alleviate these interference issues. For example, the vertical mate 9155-800 series enables vertical battery insertion due to a unique contact spring design. As shown in Figure 1, the mating surfaces of this contact can be connected at any angle without fear of damage. This same contact series can be used for horizontal board-to-board connections just as well. The 9155-800 makes a reliable connection as two boards are linearly pressed against each other with a variable gap ranging from 0.1 mm to 1.10 mm.

Miniaturization

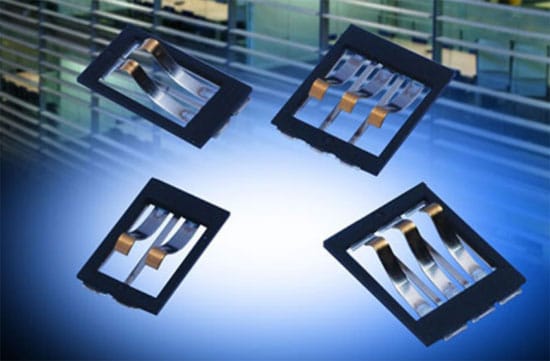

PCB real estate is a premium with most modern electronic devices. As a response, KYOCERA AVX developed the 9155-200 family to reduce both the x and y physical dimensions. These contacts save 50% in volume over the initial 9155 series compression connectors and are rated at a total of 3 amps per contact on 2.5 mm centers.

In addition to the 200 series, the established 9155-100 product family features an ultra-low z-height profile, with a compression height of as low as 1.3mm. The sweeping contact design offers a 0.7mm deflection range, extended contact wipe, and over 40 grams of contact force at minimum operating deflection. All combined, this connector is rated at a durable 5000 mating cycles for mechanical endurance.

Pitch and Configurability

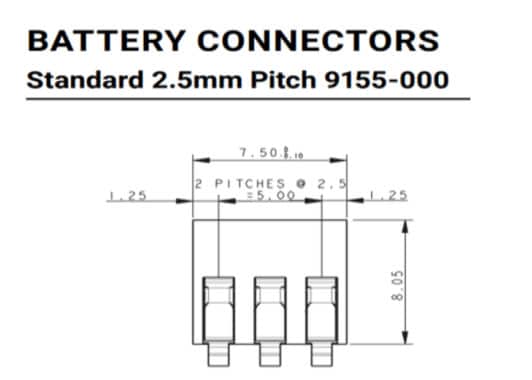

Connector pitch is a complex feature to specify in any electrical connection. Regulatory requirements often stipulate minimum creepage and clearance constraints, while industrial design and consumer requirements often trend in the opposite direction of margin. Traditional battery contacts have long been successful using a prevailing pitch of 2.5 mm, center to center, as shown in Figure 5.

In response to market needs, KYOCERA AVX innovated the connector design to reduce the pitch to 2.0 mm in the 9155-700 part family. The narrower pitch allowed for a 6-position connector.

The latest development in this trend was recently released with a mere 1.27 mm pitch 9155-021 family. As miniaturization continues, the capability to achieve battery connector pitches down to 0.8 mm is already on the horizon.

In addition to a wide range of pitch options, many KYOCERA AVX battery connectors offer the feature of being stacked end to end. This means, for example, that a three-position and two-position connector can be placed next to each other to create a five-position device that maintains the contact pitch across its entire length. This allows for the highest level of flexibility when

designing battery and board-to-board contact solutions that may require particular pitch or position specifications.

Conclusions

KYOCERA AVX offers one of the broadest and most advanced product lines of battery connectors on the market. With various height, pitch, and orientation options, these contacts enable battery-operated products and removable modules to be highly reliable, aesthetically pleasing, and functional.

KYOCERA AVX is eager to partner with customers that require innovative battery connector solutions for their applications.