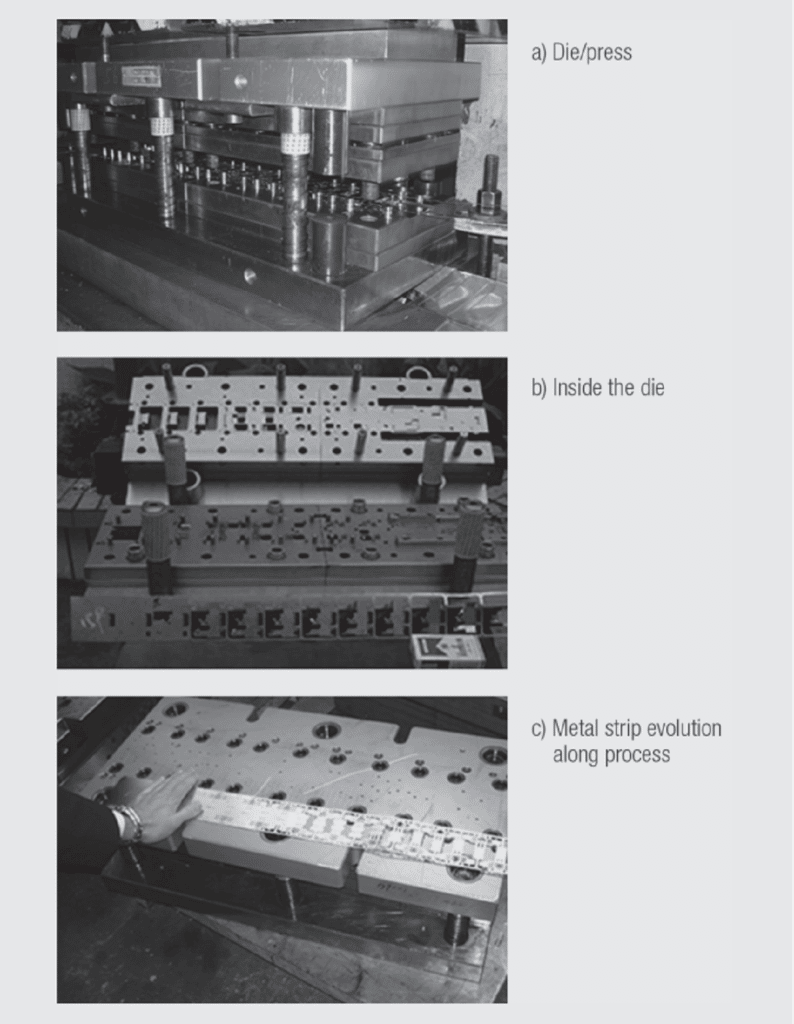

Stamping process is used to convert blank metal strip into contacts or shields by cutting and forming it. The press brings the pressure to the die which performs cutting and forming steps.

Figure 1.31a illustrates the die into the press, when figure b shows inside the die (in between the two parts). On the c figure we can see the metal strip evolution along the process (from a blank metal strip down to a typical RJ45 metallic shielding)

The vast majority of connector contacts are produced by stamping and forming processes using multi station dies that perform a variety of stamping operations including piercing, blanking, shearing and bending among others. The design of the dies and the sequence of the various stations depend on the complexity of the contact design with receptacle contacts being mostly more complex than those of plug contacts.