Design and material change are also necessary for contacts, particularly the termination end of contacts. THR compatibility places additional requirements regarding the pin length. This is particularly true if the connector is intended to be both through hole and THR compatible.

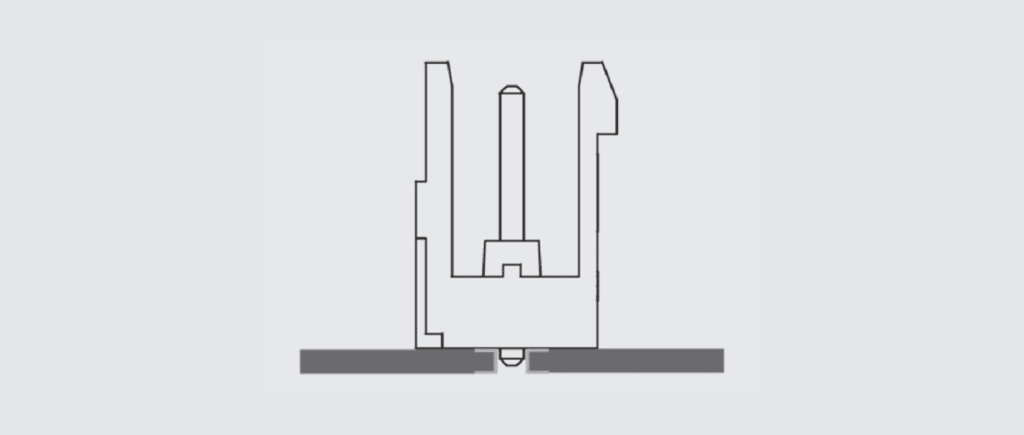

If the pin is too short, as per Figure 2.84, the stability of the pin in the through hole may be compromised with resulting handling problems during the reflow assembly process. In addition, the soldering of a short pin may not produce a solder joint that meets the requirements of the IPC-A610D Standard.

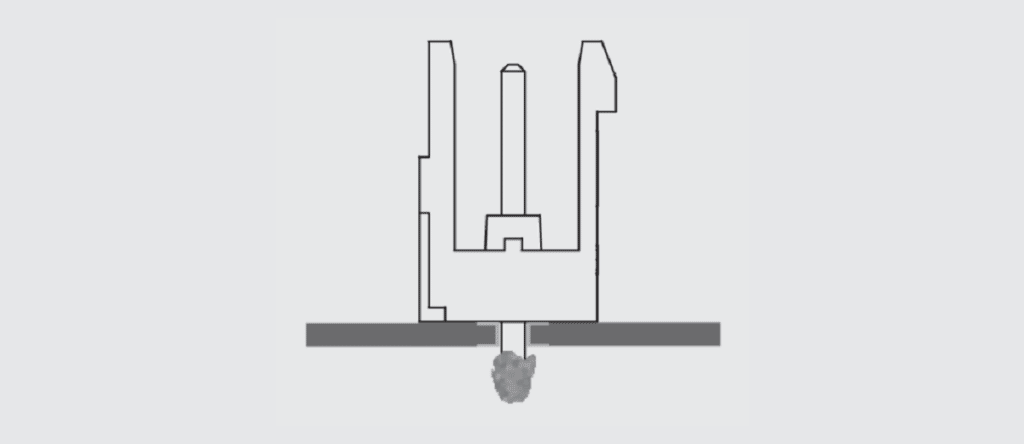

A pin that is too long may push some solder paste out of the PTH to accumulate on the end of the pin. If this occurs the solder paste on the end of the pin may ball up rather than wicking up into the through hole during reflow and compromise the solder volume and the soldered connection to the through hole plating.

To minimize the potential for these problems the pin length protruding from the PCB should be discernible in the solder and shall not exceed 1.5 mm. Würth Elektronik chose a 2.6 mm pin length for its THR contact pins to be compatible with PCB thickness from 1.6 mm to 2.3 mm. The pin centering in the PTH is also important to optimize the solder flow.

Solderability requirements for THR compatibility may dictate changes in the pin plating from bright tin to matte tin. Inadequate control of the brighteners may compromise the solderability of bright tin plated pins due to surface film formation during storage of connectors.