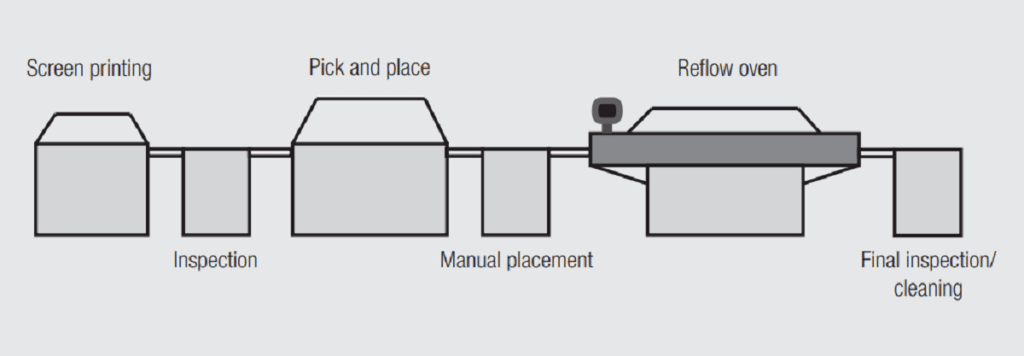

The basic requirement of a THR manufacturing process is to ensure compatibility with the existing SMT manufacturing process, typical stages of which are illustrated in Figure 2.86.

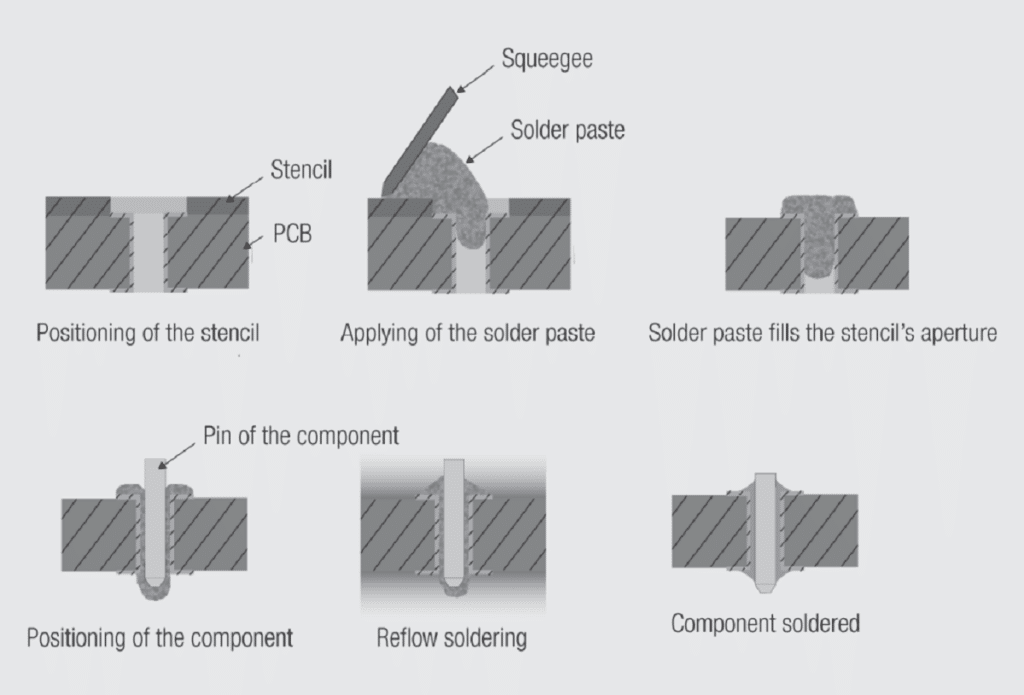

Stage 1: Screen printing: the solder paste is applied to the PCB.

Stage 2: Inspection: ensures the dimensional control and alignment of the screen printing process with the PCB.

Stage 3: Pick and place: puts the SMT, and any connectors which may also be pick and place compatible, onto the screened solder paste.

Stage 4: Manual placement: connectors are manually inserted into the PTH of the PCB.

Stage 5: Reflow oven: reflow soldering of the components onto/into the PCB via reflow soldering processes, typically vapor phase or convection reflow.

Stage 6: Final inspection: inspection using appropriate methods to ensure the proper placement of components and satisfactory soldered joints.

Stage 7: Cleaning: removes possible flux residues.

Figure 2.87 shows the status of the PCB with respect to the solder paste and soldering process through the manufacturing line. The first three illustrations show processes occurring in the screen printing stage as the solder paste is applied to the PCB, the fourth illustration shows the PTH after the connector insertion with the solder paste distribution in the PTH, the last two illustrations show the reflow process and the configuration of the soldered component.