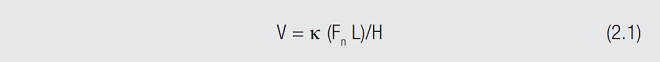

The variation of mating wear/durability as a function of contact force is a good example of normal force optimization. The kinetics of the wear process were discussed in Chapter I/1.3.2 The Mechanical Interface: Friction and Wear/Durability. The following equation provides a parametric format for discussion of some of the major factors influencing the wear process.

where, V is the wear volume, Fn is the contact normal force, L is the mating length or fretting distance, H is the hardness, and k, the wear coefficient, is a parameter including effects of roughness, lubricity, contact geometry and normal force.

The wear volume, V, represents the volume of material removed, the wear particle in Figure 1.17 (Page 30). It can be related to the loss in thickness of the contact finish from the fact that V is the product of the contact area and the thickness removed.

Note that given this formulation, the thickness removed increases as the contact area decreases.

The dependence on L, the mating length or fretting length, is straight forward. Similarly for hardness, H, in that hard materials wear less than soft materials for a given contact configuration and contact force.

Note that the contact force, Fn, appears in two places in the equation. V increases linearly with contact force for a given value of k and Fn also appears, parametrically, in k itself. k is complex in its variation, with multiple parameters. For example the wear rate for a lubricated surface will be lower than that for a non lubricated surface, but as contact force increases the effects of lubricity may be overcome by a transition from a burnishing to an adhesive wear regime. Thus wear rates can vary significantly depending on the interactions among the multiple parameters included in k. The key point about contact force and wear is that wear rates increase linearly with Fn and can increase discontinuously and dramatically if the wear kinetics transition from burnishing to adhesive wear. This is an important consideration at high contact force.