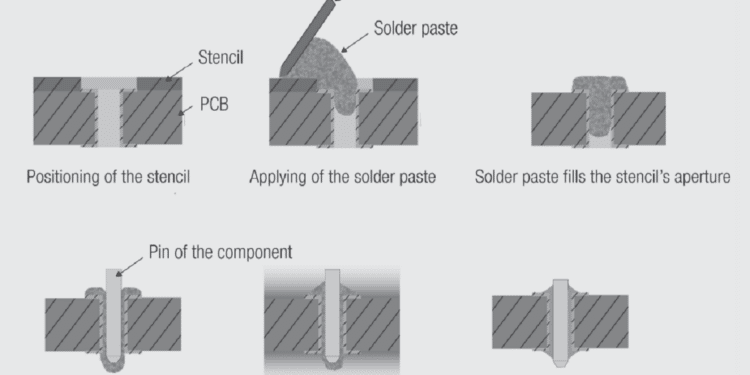

The screen printing process is particularly important because it determines the amount of solder paste that will be applied to the PCB and therefore, the amount of solder in the final soldered connection.

The amount of solder, in turn, determines whether the applicable solder joint inspection criteria will be met. The design guideline for the amount of solder needed is that the solder shall be sufficient to fill the free volume of the PTH, that is (VPTH – VPIN). The solder paste is a combination of soldering flux and metal alloy, with the metal content being around 50% of the volume of the solder paste. Therefore, it is necessary to apply twice as much paste than the free volume between the pin and the PCB hole. The flux components will either evaporate or be removed during the final cleaning process.

The following parameters have to be considered to maintain process control of the solder paste volume:

• Choice of the stencil thickness and design

• PCB design and connector layout

• Choice of the solder paste

• Speed, pressure and angle of the squeegee used to apply the solder paste to the PCB

The first two parameters determine how much solder paste will be retained in the stencil volume. The second two parameters will determine how well the solder paste will fill the PTH and stencil aperture.