This article written by Gaby Cristian Mindreci, president of Performance Interconnect SAS is intended to summarize the current environment linked to the evolution of through-hole solderless connections in spaceflight embedded computing.

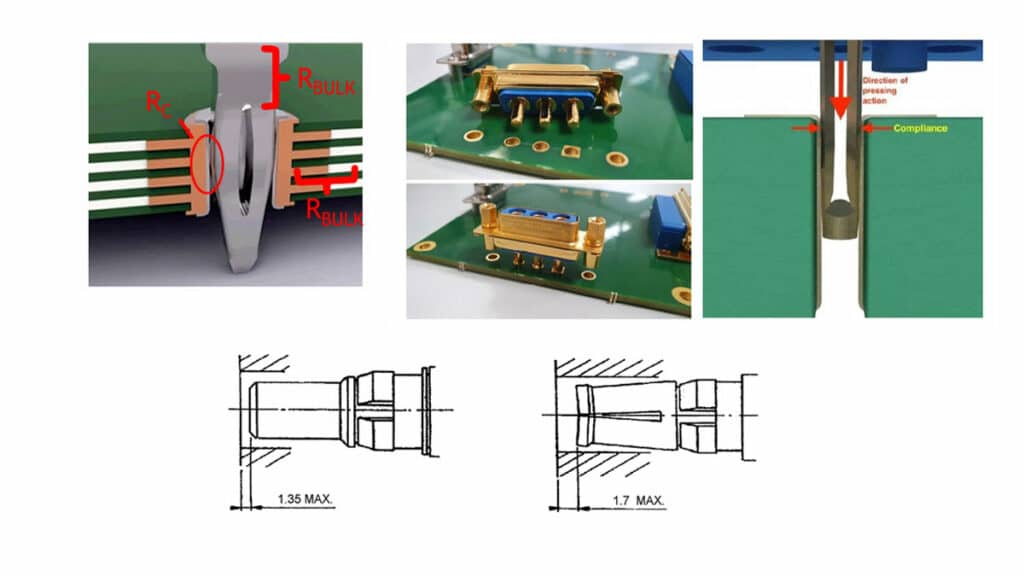

The space industry is increasingly turning attention towards solderless connections to PCBs. Ongoing studies are in place overseen by both ESA and NASA. Connector manufacturers respond with solderless solutions employing various tweaks of contact termination geometries using in-hole cross-sectional deformation known universally as press-fit.

Through-hole press-fit is a mature technology and it has been employed reliably in automotive, industrial, and telecom electronics increasingly over the last 70 years.

In many cases, press-fit has been used in military, aerospace, and even space-flight applications however there has been a lack of specifications related to solderless high-reliability, harsh environment performance requirements… But that landscape is changing.

At ESTEC, The European Space Research and Technology Centre, with the participation of CNES, The French National Space Agency, reliability studies related to compliant press-fit technology started since 2018 and by November 2021, the ESCC Detail Specifications No. 3401/098 and No. 3401/099 have been released extending to D-Subminiature connectors in standard, high-density and combo-D configurations with compliant press-fit terminations.

The two specifications are linked here:

- https://escies.org/download/specdraftapppub?id=4067

- https://escies.org/download/specdraftapppub?id=4474

ESTEC’s attention extends further with three different activities currently in-progress, related to evaluating distinct solderless interface technologies, namely compliant press-fit and S-FECT which stands for Slide-Fit Electrical Contact Termination. These reliability studies revolve around the newly adopted Compact PCI Serial Space Specification by a dedicated working group called ADHA, who, under ESA’s leadership, is in charge to develop and maintain an advanced and open embedded computing architecture to be adopted by the European space community.

To learn more about ADHA:

The compact PCI Serial Space Specification was released by PICMG, The PCI Industrial Computer Manufacturers Group in August of 2017. This specification is focused on system architecture and interoperability but doesn’t contain performance requirements related to components or specifically to connectors.

With the most dominant footprint yet, released by the VITA Standards Organization, the Space VPX specification aka ANSI/VITA 78.0-2022, is an open standard for high-performance fault tolerant interoperable systems for spaceflight and other high reliability applications. Space VPX, originally released in 2015, has secured the widest global adoption and is currently the “default” embedded computing architecture for military and aerospace critical missions. However, this specification also does not define connector reliability and performance requirements.

In a recent Space VPX Interoperability Assessment conducted by NASA, The National Aeronautics and Space Administration, the following statement points the obvious:

“During the Space VPX connector analysis, potential reliability issues were raised regarding the attachment of Space VPX connectors to PWBs, including the ability to tolerate shock and vibration environments. While these issues are beyond the scope of this assessment, they are critical to ensuring the reliable use of Space VPX modules for NASA missions.”

The full assessment can be found here:

NASA is recognizing the need for the adoption of solderless interface technologies and is taking proactive steps towards the implementation of an upcoming standard, NASA-STD-8739.11 which “will open the door for a broader review of press-fits for NASA missions” to quote the last words from the NASA released presentation linked herein:

Conclusion:

Solderless through-hole technologies utilized in embedded computing systems for critical missions will attract attention with increasing intensity distributed amid regulatory agencies, the user base, and connector manufacturers.

The spotlight falls onto connector manufacturers because the competition is on. Elements such as the manufacturers’ know-how, the materials employed, the technical parameters, the performance achieved, the ease of use, repairability, and overall reliability, shall contribute to the future success of each product.

The article is also intended to raise awareness of the upcoming 5th Space Passive Component Days International Symposium which will take place from October 15th to the 18th, at the ESTEC facility in Noordwijk, The Netherlands. The SPCD International Symposium is the premier technical conference dedicated to passive components for spaceflight applications. On October 15th, from 13h00 to 14h10, a pre-event EEE Seminar, organized by Tomas Zednicek Ph.D., President of the European Passive Components Institute, will explore emerging solderless interconnect technologies and their significance for the space industry. Guest speaker, Gaby Cristian Mindreci, president of Performance Interconnect SAS, will present an unbiased and detailed outline on state-of-the-art connectors using solderless through-hole technologies. After the seminar, participants shall have a clearer understanding of the cutting-edge developments and trends in solderless interconnects and will be aware of the challenges associated with these components and the critical reliability factors to consider.