New developments in semiconductor materials and manufacturing processes continue to lead to increasingly smaller sensors, processors, and devices. There are still areas, however, where space limitations are hindering technological advancement and user adoption.

One of these areas where the size of technology has slowed progress is in augmented- and virtual-reality (AR/VR) applications. Before we dive into the reasons why — and explore a new development helping to solve the challenge — let us look at a quick overview of AR and VR.

AR/VR 101

AR is a technology that superimposes an image over a view of the actual user’s environment. This can be accomplished via a handheld device (such as a smartphone), a user–worn headset or glasses, or a projection (such as heads–up displays common in some vehicles).

A few common uses of AR include providing information about the user’s environment, gaming, and for safety data. VR, on the other hand, does not use aspects of the real world but instead immerses the user in a virtual environment. For this reason, VR typically requires the use of a headset, which completely covers the user’s eyes and blocks out the world around them.

Up until now, adoption of AR and VR — while steadily growing — has been limited. Even with significant investments from organizations such as Meta, virtual reality remains a relatively niche market. But why?

WHEN IT COMES TO WEARABLES, BULKY IS OUT

A large part of the slow adoption of this potentially groundbreaking technology is because of its footprint. AR, in particular, holds incredible promise for use in wayfinding, translation, infotainment, and even medicine. But these uses require wearing bulky lenses, glasses, or other headwear — or, alternatively, holding up a smartphone to view the AR environment.

Simply put, no one wants to wear heavy, unbecoming glasses all the time or perceive the world through the 6–inch screen of their smart device. Furthermore, wearing a bulky, heavy device for any length of time can be very uncomfortable.

MEET THE MOLEX QUAD–ROW BOARD–TO–BOARD CONNECTOR

For years, the size of connector technology is one of the biggest challenges for engineers who want to limit the size of their device while designing wearable and embedded systems. While semiconductors have become increasingly smaller, the communication standards have mostly stayed the same size, and even with custom cabling, oftentimes the limiting factor for system size was the cable and its corresponding connector.

For AR and VR solutions to succeed, the form factor needs to be small, lightweight, and comfortable for the user. At the same time, AR and VR technology demands significant processing power and high–quality displays. To meet this demand, design engineers require a connector that offers robust communication capabilities while minimizing footprint and weight. The quad–row connector from Molex meets these needs by offering a variety of connectivity options in a package that is significantly smaller than other solutions on the market.

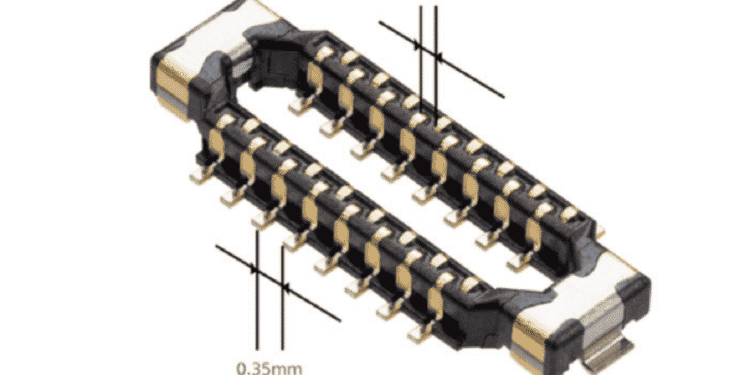

At the heart of the quad–row connector’s performance gains is its staggered–circuit layout, which offers up to 30% space savings over conventional connector design. The connector achieves this through its design that positions pins across four rows with a signal contact pitch of 0.175 mm. This staggered–circuit layout shines in applications in which space optimization is a top priority, including in smartwatches, smartphones, wearables, and — yes — AR and VR devices.

“Molex continually drives connectivity innovations in support of increasingly smaller yet more powerful devices,” said Justin Kerr, vice president and general manager of the Micro Solutions Business Unit at Molex, in a recent press release about the tech. “With the high–density quad–row board–to–board connectors, our customers now can squeeze more features, sensors, and functionality into increasingly tight spaces without compromising device performance. As a result, Molex is setting a new connectivity standard for space optimization.”

With a soldering pitch of 0.35 mm, manufacturers can assemble the connectors using standard surface–mount technology processes, which means that as AR and VR systems gain popularity, production can scale accordingly. As AR and VR systems are often integrated into moving objects (such as vehicles) or worn, it is also critical that connectors can withstand motion, drops, and other harsh conditions.

Fortunately, Molex quad–row connectors are built with interior armor and insert–molded power nail, with reliability and robustness in mind. Connectors are also available in different configurations and are currently offered in 32– and 36–pin varieties, with 64–pin configurations coming soon. In fact, there are plans underway to support a 100–pin version of the quad–row connector, positioning this technology for use in some truly advanced AR and VR system designs.

Another benefit for design engineers interested in putting these new connectors to use in their AR and VR applications is that the technology has already been put to the test. These quad–row connectors were initially developed in partnership with engineers from a major smartwatch manufacturer that needed a flexible, robust, and compact connector solution for use in its wearable smartwatch devices

AR AND VR ARE JUST THE START

For hundreds of applications, saving space and weight is a huge concern. Whether it is in AR, wearable fitness trackers, gaming devices, or automotive applications, engineers are constantly looking for ways to reduce the footprint of their designs while still using high–performance and robust connector solutions.

With its small size, robust design, and high pin count, the now commercially available quad–row connector from Molex seems to fit the bill, and you can expect to see engineers deploy this solution in AR and VR designs and more.