With this basic introduction to connectors in hand, consider now a more detailed introduction to connectors and the components of a connector. A functional definition of a connector is:

A connector is an electromechanical system which provides a separable connection between two subsystems of an electronic system without an unacceptable effect on the performance of the device.

The bolded terms in this definition are the most significant characteristics of a connector.

A connector is an electromechanical system in that it creates an electrical connection by mechanical means. As previously mentioned, deflection of mechanical springs creates a force between the two halves of the connector on mating which creates areas of metal-to-metal contact at the mating interface. The metal-to-metal interface provides the connection where the current flow takes place.

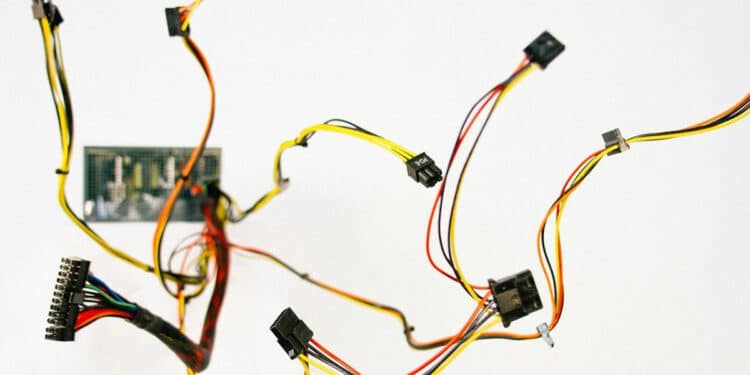

A separable connection, separability, is the primary reason for using a connector. Separability may be required or desirable for a variety of reasons. Manufacturability considerations include allowing for independent manufacturing of subassemblies or subsystems with final assembly taking place at a central location. As the complexity and functionality of electronic systems continues to increase this manufacturing flexibility is increasingly important. One example is the ability to “custom build” a personal computer to your own specifications. A second example is to allow for maintenance or upgrading of components or subsystems as increased functionality becomes necessary. Finally, portability and the ability to support an increasing range of peripherals in a laptop computer require separable connections for multiple use of an input port or usage at multiple locations. The number of mating cycles, mate and unmate, needed depends on the reason separability is required. Manufacturability reasons generally require only a few mating cycles while portability and multiple port usage may require several hundred mating cycles in a laptop computer.

While these separability capabilities are virtues, separability, by definition, introduces an additional interface into the system. This interface must not introduce any unacceptable effects, in particular any unacceptable electrical effects, on the system performance. The most significant potentially unacceptable electrical effect relates to the resistance across the mating interface: both the magnitude and stability of the resistance. Resistance increases are of particular importance in power transmission for two reasons. First, the Joule, or I2 R, heating as current, I, flows increases as the electrical resistance, R, increases. Joule heating increases the temperature of the contacts which, in turn increases the degradation rate of the interface, up to and including, melting or open circuiting of the interface. Second, large increases in resistance can impact the signal transmission characteristics in digital applications. Thus, the magnitude and stability of the resistance across a mating interface is a major consideration in connector performance and reliability. Interface resistance will be discussed in detail later in this chapter.