The vast majority of connector contacts are stamped and formed from copper alloy strip. This discussion of copper strip processing begins with the cast slabs of the chemical composition of the desired copper alloy, say 70 percent copper and 30 percent zinc for cartridge brass.

The dimensions of the slabs vary with the alloy and the casting process and vary from a few centimeters to over 15 centimeters (one to six inches) in thickness, 0.3 to 0.9 meters (ten to thirty inches) in width and up to eight meters (25 feet) in length. The thickness of the strip used for stamping and forming of connector contacts is of the order of 0.04 to 1.0 mm (1.0 to 40 thousandth of an inch) so a significant decrease in the thickness of the cast slab is necessary to attain this thickness at a controlled value of yield strength and formability. This reduction is real zed through two different rolling operations, hot and cold rolling. As with electroplating, the rolling processes are proprietary and only general comments will be provided.

Hot rolling is used to accomplish the major reductions in thickness, from the original thickness of, say 10 centimeters (four inches) down to, say one centimeter (0.4 inches). The temperature of hot rolling is critical in that the metal must be, and remain, hot enough to avoid work hardening during the entire process which may include several passes through the hot rolling mill. By controlling the temperature the final hot rolled strip will be in an annealed (soft) condition with a controlled grain size. Suffice it to say that grain size influences the cold rolling process used to establish the final mechanical properties of the strip.

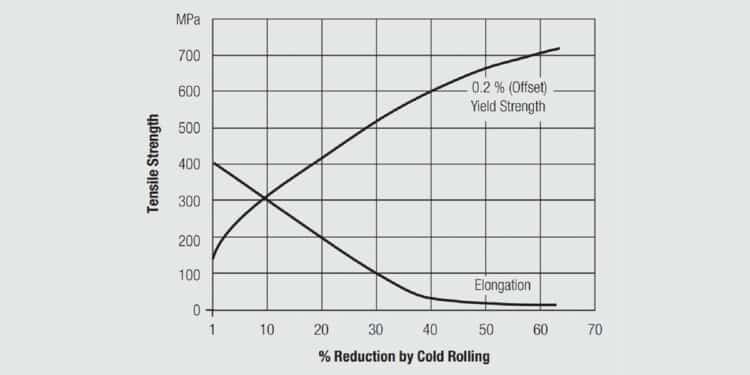

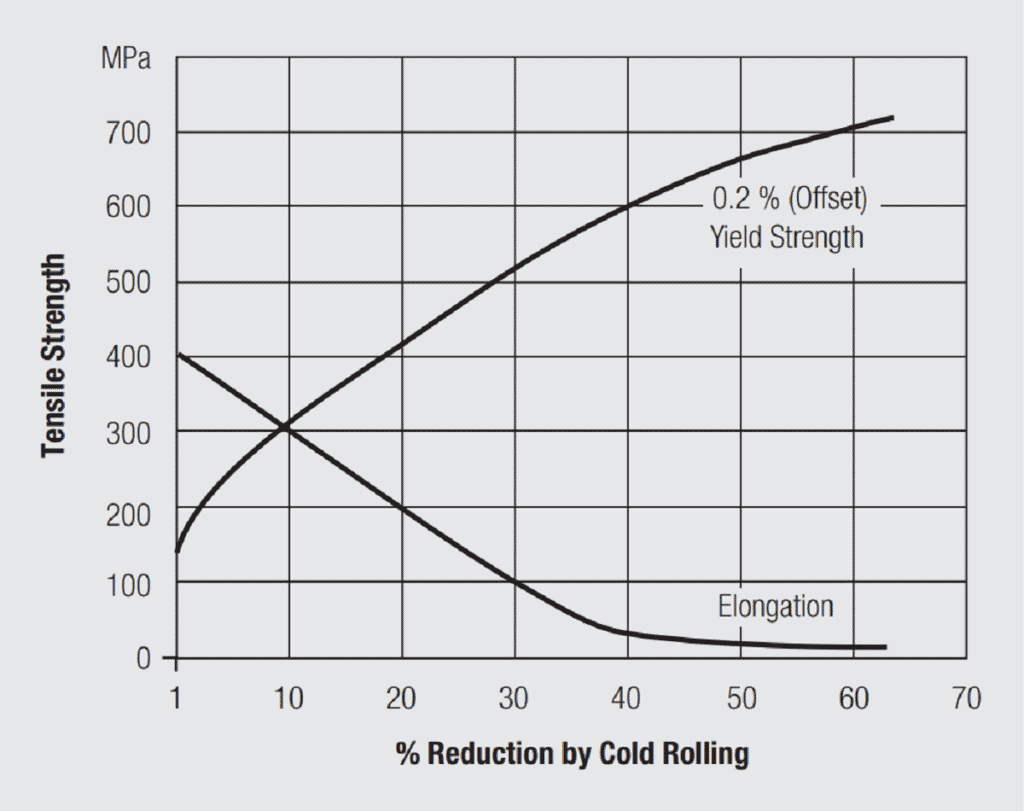

The cold rolling process takes the strip down from the hot rolling thickness of ten millimeters (0.4inches) to the final specified strip thickness, say 0.4 millimeters (0.016 inches). During the cold rolling process the yield strength and elongation of the strip are also established. Recall that deformation of a metal, in this case reduction in thickness by rolling, work hardens the metal increasing its resistance to deformation or increasing its yield strength. Work hardening also decreases the ductility of the metal, the amount of deformation it can support without cracking. This means that only a limited amount of reduction in thickness can be realized in cold rolling without damage to the strip. In practice a specified reduction in thickness is taken and the strip is then annealed, held at an elevated temperature for a specified time, to return it to its soft condition when it can then be subjected to another reduction in thickness. This roll/anneal process is repeated as often as necessary to get to the thickness required for the final annealing and rolling process which is when the mechanical properties of the strip are established. The final anneal establishes the final grain size of the strip, and the final reduction in thickness establishes the yield strength/elongation. The relationship between reduction in thickness and mechanical properties, in particular yield strength and elongation, is known for each copper alloy. A generalized example is provided in Figure 1.30. For a given connector design, the design yield strength is determined by the contact normal force requirement, as will be discussed in Chapter II/2.2 Contact Springs. The elongation requirement depends on the forming necessary to realize the conformation of the contact spring. As an example, say a cantilever beam receptacle contact normal force requirement dictates a yield strength of 500 MPa (75 ksi) and an elongation of greater than 5 percent is necessary. For the material indicated in Figure 1.30, a 30 percent reduction in thickness on the final cold rolling pass will meet the yield strength requirement with an elongation of just under 10 percent, which also meets the elongation/ductility requirements.

This description of the hot and cold rolling processes taking a copper alloy from a cast slab to a specified strip thickness and mechanical condition is, in principle, very straightforward. But the process controls, both thermal and mechanical, are very demanding as is the surface condition of the rolls and the supporting structures of the rolling mills that are used. Tradeoffs among the various thermal and rolling process variables used by copper strip providers explains the variation in the comparative relationship between yield strength and formability among suppliers.