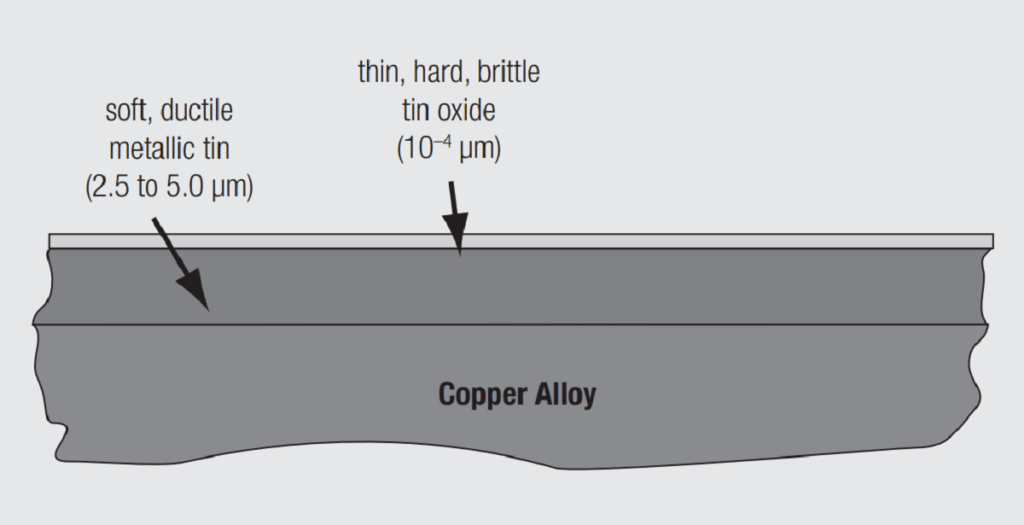

Tin is the dominant non-noble contact finish due to its widespread use in connectors for commercial and industrial applications. Tin finishes are generally electroplated, though reflowed tin coatings are also used. The thickness of electroplated tin is generally in the range of 2.5 to 5.0 µm (100 to 200 microinches) with reflowed coatings being somewhat thicker.

Tin provides corrosion protection to the contact spring due to the self limiting tin oxide film on the tin surface. As indicated in Figure 2.4, the oxide layer is very thin, hard and brittle and is readily displaced on mating of the connector resulting in tin-to-tin metallic contact areas. The major limitation to the use of tin as a general purpose connector contact finish is the fact that a tin-to-tin contact interface is susceptible to reoxidation if the interface experiences small scale movements due to mechanical or thermal stresses in the connector application environment. This degradation mechanism is called fretting corrosion.

Nickel and silver are also used in connector applications. Nickel has an even thinner oxide layer on its surface than tin. Nickel is most commonly used in battery contacts and also in high temperature applications. Silver surface films are primarily sulfides, tarnish films, which are also readily displaced on connector mating. Silver is used primarily in high current contacts due to the high electrical conductivity of silver and a better resistance to arcing damage compared to gold or tin contacts.