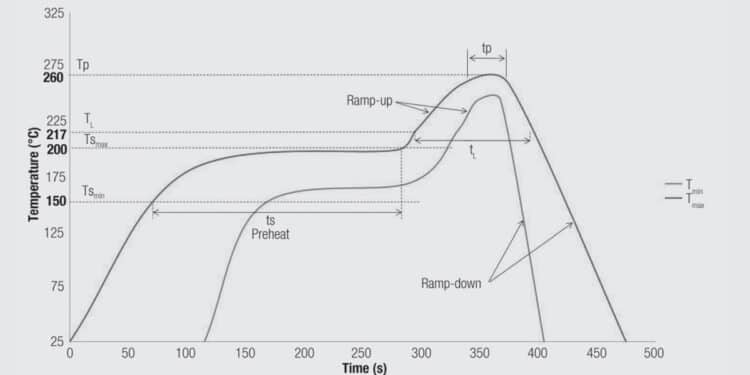

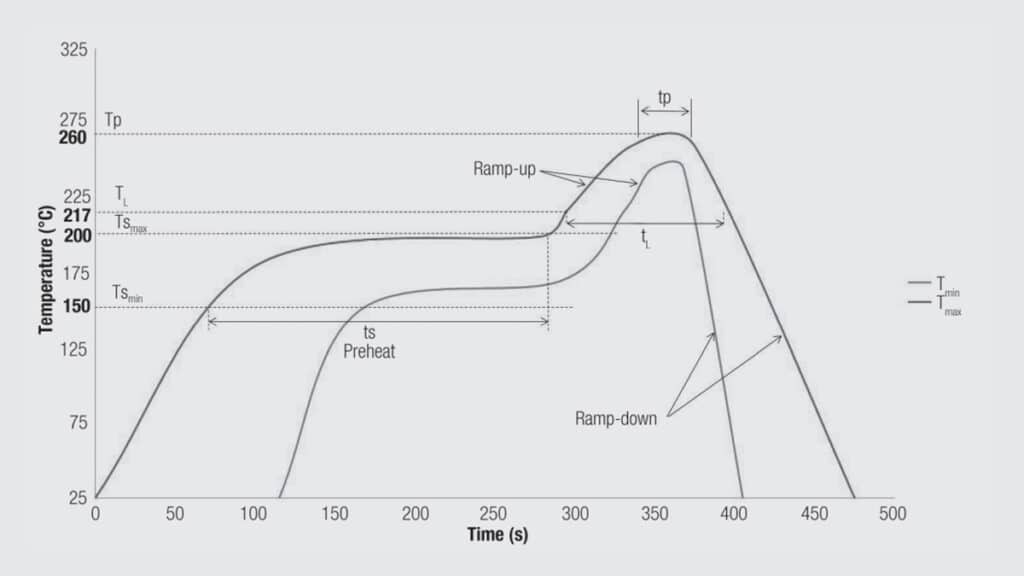

As noted previously, the THR reflow practice is basically identical to the SMT reflow practice. As such, it can be accomplished through infra-red convection and vapor phase soldering. In either case, the temperature profile of the reflow soldering process is critical to a consistent and reliable reflow soldering. Figure 2.100 shows a representative temperature profile recommended for lead free infra-red convection reflow soldering according to IPC/JEDEC J-STD 020D.

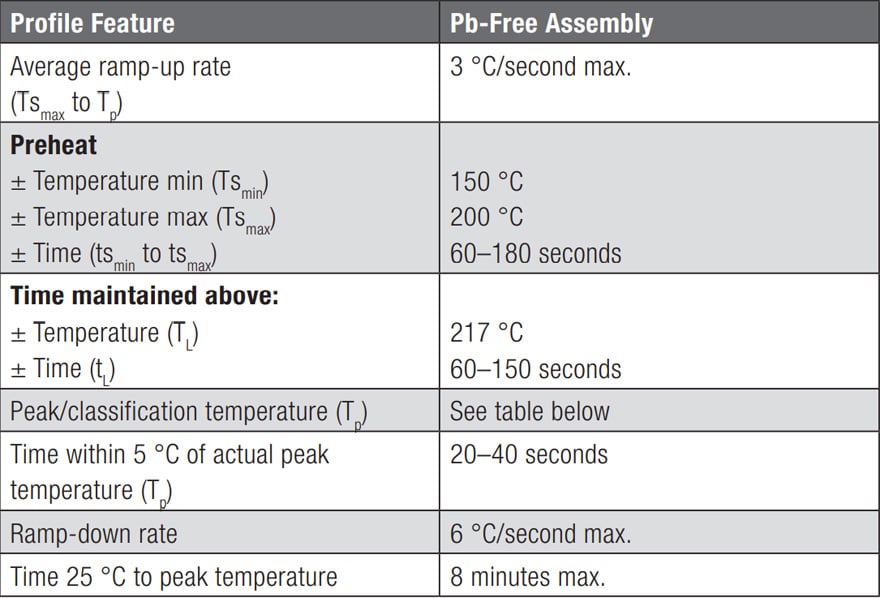

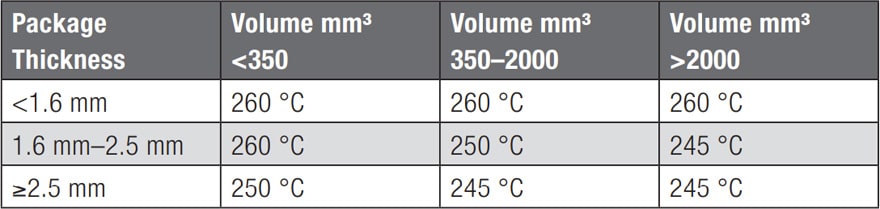

Process details are provided in Table 2.5. Peak temperature recommendations are provided in Table 2.6

Source:

Wurth elektronik