Whenever possible, it is desirable to use automatic pick and place technologies to insert the connectors into the PCB PTH.

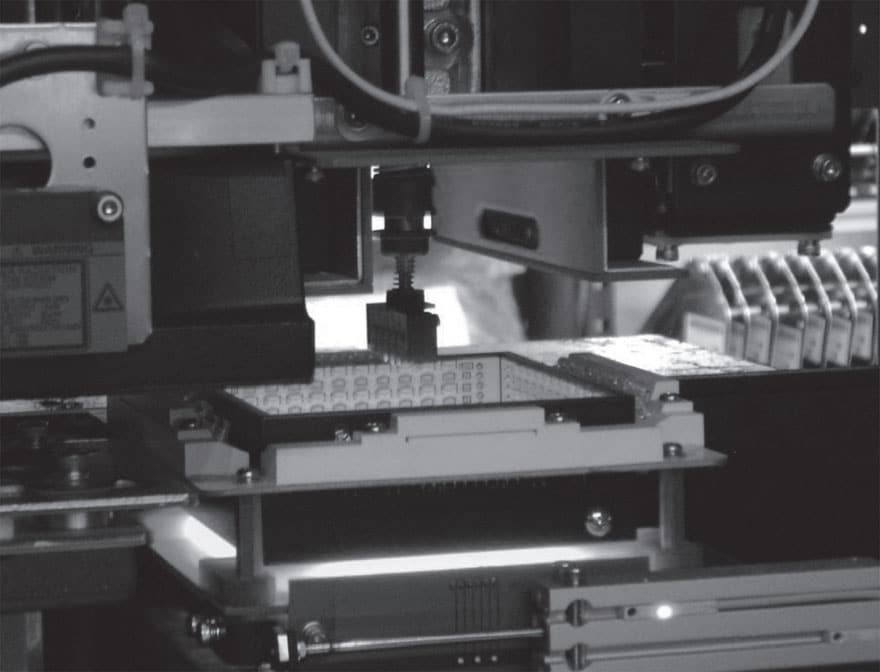

Figure 2.96 illustrates a typical pick and place insertion process. The size and configuration of the connector housing will impact the ability to use pick and place practices. Special features may need to be designed into the housing to enable the pick and place process. In our example of a WR-TBL vertical THR version, a plastic cap is positioned on the top of connectors (Figure 2.97) for pick and place machine handling.

For horizontal version, this cap is not needed as it can be handled directly from the top of the housing.

In addition, a suitable packaging has to be used in order to optimize this process for mass production. Commonly, the SMT and THR components are packed in tape and reel packaging, as illustrated in Figure 2.98, in order to be useable with automatic machines.

Components and connectors intended to be mounted on a board are packaged in reels and placed in the pick and place feeder, as illustrated in Figure 2.99. The pick and place feeder then positions the correct component automatically on the board as previously shown in Figure 2.96.